CHALLENGE:

A start-up company in the process of developing and manufacturing 3D printing solutions for wide-scale production, approached DRF expressing their need for a custom solution to control a newly introduced printer; specifically targeting 3D composite material, in order to:

1.) Reach both their cost and technical goals.

2.) Achieve their business objectives.

DRF’S SOLUTION:

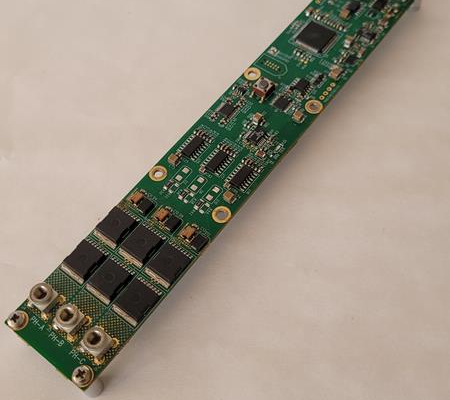

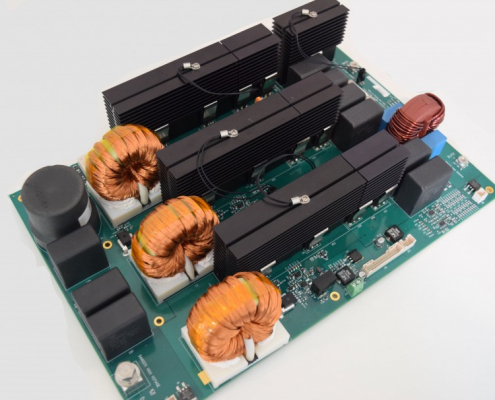

DRF helped to design and develop a custom control board and tailored it to meet the client’s specifications. In order for us to also meet their low-cost requirement, we included several safety “watchdog” circuits, and proposed an 8-bit microcontroller (Atmel atmega 328p), commonly found on the Arduino, for this particular design.

Working from the supply voltage, first, DRF provided the customer with a DC/DC power supply, consisting of multiple outputs, for housekeeping power. Due to the precise requirements necessary to control the loads; such as heater beds, air pumps, and many stepper motors, custom circuitry was needed. A zero-crossing circuit was also developed to control the air pump, and several Solid-State Relays were included in the design, as well.

Key Features:

- A zero-crossing circuit, detecting full-wave triggering (two pulses per one cycle)

- 120/230 V operation

- Four Solid State Relay (SSR) circuits, including an AC Snubber

- An 8-bit microcontroller

- Four channels for temperature measurement