Design Guide To Creating Your Next Inductor

Welcome to the December edition of DRF’s newsletter! This month, Saad Thabit presents a guide for designing a custom inductor, using C Cut-Cores.

Do you have a new inductor design in mind, but don’t know what to use?

Look no further! Amorphous metal and nanocrystalline are the best available options for your designs requiring the highest efficiency, and here’s why:

- High permeability leads to increased inductance and reduces winding turns, resulting in reduced I2R losses.

- High saturation induction will reduce size of the inductor.

- High frequency will range from 50Hz up to 100KHz.

- High operating temperatures can reach up to 120℃.

- Low coercivity increases the efficiency, and reduces hysteresis loss.

- Low core loss reduces energy consumed, and minimizes the temperature rise.

Filter inductor designs, the values of the inductance, inductor current, operating frequency, ripple current and power losses will be determined by the following application:

V_ind = 2*π*f*L*I_Peak

Where:

- f = Inductor operating fundamental frequency

- L = Inductance value

- I Peak = Inductor peak current

How to calculate the cross-sectional area product Ap:

Ap = [V ind*I peak*10^4] / [Kf*Ku*B peak*f*J]

Where:

- Ap units are in cm4

- Kf =4.44 for sine waveforms

- Ku is the core window utilization fill factor

- B peak is the flux density in Tesla

- f is the operating frequency in Hz

- J is the current density in Amp / cm2

The Ap product of a C-type cut core is the product of the available window area (Wa) of the core in square centimeters (cm2), multiplied by the effective cross-sectional area (Ac) in square centimeters (cm2), which may be stated as:

A p = W a x Ac [cm4]

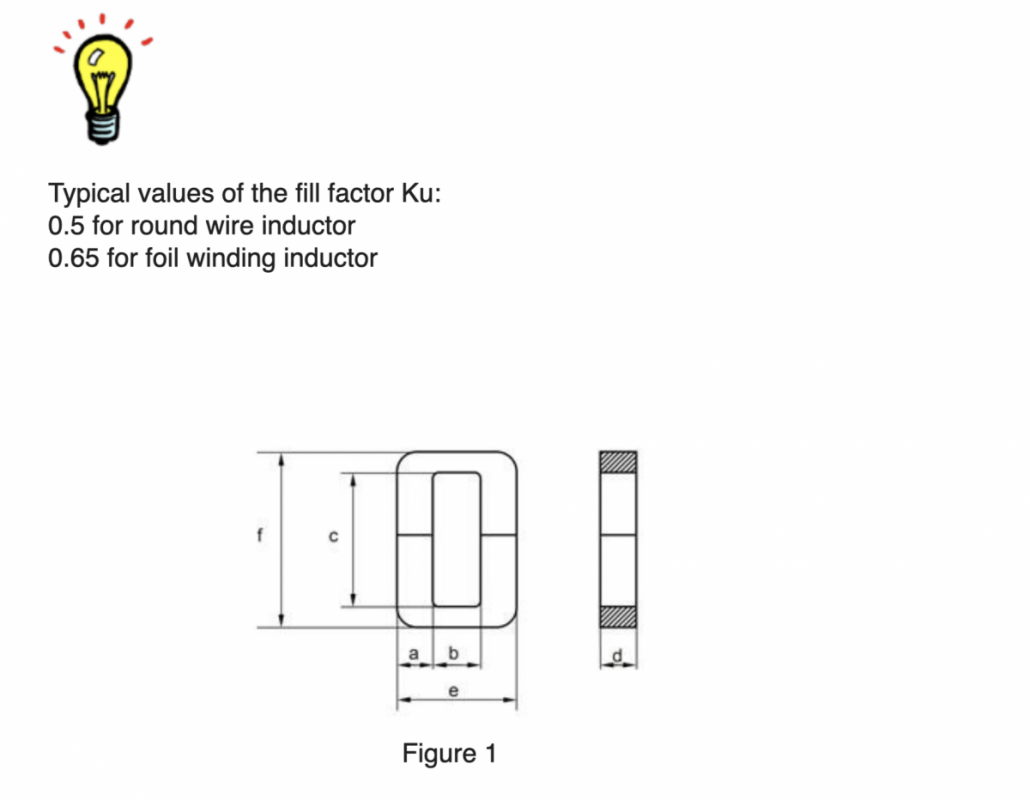

Figure 1 (shown above) shows the outline form of a C-core type inductor; typical of those shown in the catalogs of suppliers.

From this, it can be seen that [Wa] is the BC product, and [Ac] is the AD product.

The AC inductor must support the applied voltage V ind. The number of turns is calculated from Faraday’s Law, shown below:

N = [V ind*10^4] / [L*Kf*B peak*f*Ac] [Turns]

Now, we can calculate the air gap with the equation below:

Lg = [0.4*π*N^2*Ac*10^-8]/ L

Where:

- L is the inductance, measured in Henry

- AC is measured in cm2

- Lg is the gap in cm

Keep in mind, the fringing flux will decrease the total reluctance of the magnetic path, therefore increasing the inductance, by a factor F; all of which can be found in the formula below:

F = [1+(Lg/sqrtAc) *(Ln(2*C/Lg))]

Now that our major inductor parameters have been identified, we need to determine the inductor wire size.

Calculate inductor bare wire area Awire:

Awire = I peak/J [cm2]

Select the wire from the wire manufacturer table. For reference, you can use the table supplied in this link.

Now, we have determined the wire size. If we also know the mean turn length, as well as the number of turns, then we can determine the total length of the wire. From there, we can calculate the DC winding resistance, using the formula:

R dc = MLT*N*resistance per unit length [Ohm]

Where:

Resistance per unit length as read from the wire tables for the selected wire size.

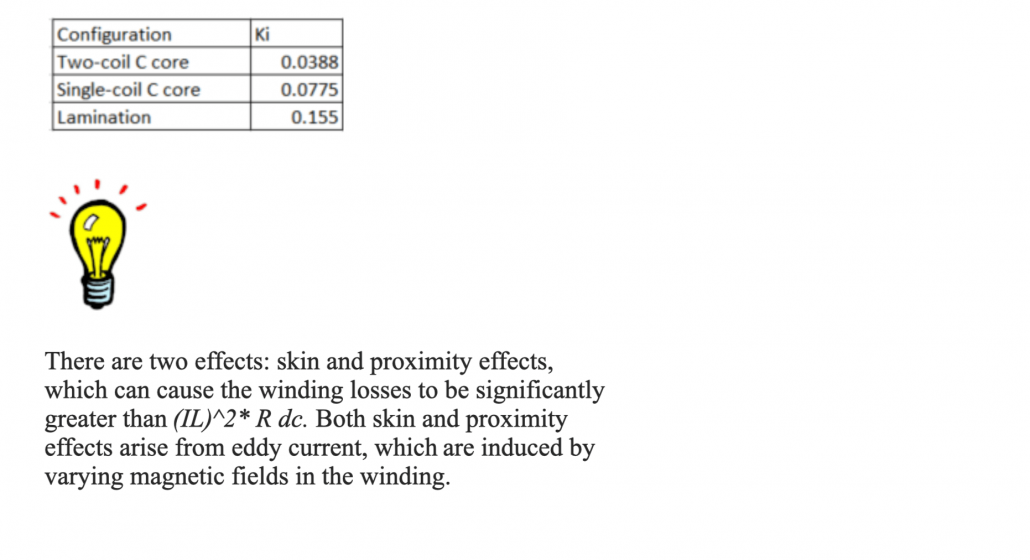

The losses in an ac inductor are made up of three components:

- Copper loss, Pcu

2. Iron loss, Pfe

3. Gap loss, Pg

- Copper Losses, Pcu

Pcu = (IL)^2 *R dc [Watts]

- Iron losses, Pfe

For amorphous metal, use the following equation:

Watt/Kilogram = 6.5 * f(KHz)^1.51*Bac(T)^1.74

For Nano-crystalline use the following equation:

Watt/Kilogram=1.8 * f(KHz)^1.53*Bac(T)^1.52

Where:

Bac is the flux density, and can be calculated using the formula below:

Bac = [ L*di] / [2*N*A] [Tesla]

Variables:

L inductance in Henry

Ac core cross section area in m²

- Gap loss, Pg

Pg = Ki* a*Lg*f*Bac^2 [watt]

Where:

- a is the core strip width in cm (see Figure 1 above)

- f is frequency in Hertz

- Lg is the gap width in cm

- Ki is the Gap loss Coefficient

To calculate total indicator losses, use the following equation:

P total = Pcu + Pfe + Pg [Watts]

From here, you can calculate the inductor temperature rise, after calculating the inductor surface area.

As the resistivity of the copper winding increases with temperature, the winding loss increases with temperature as well. In the magnetic materials, the core loss increases with the increasing temperature, above approximately 100-degrees C. The value of the saturation flux density becomes smaller with increases in the temperature.

Winding and core loss causes the temperature increase; therefore, the loss must be kept below some maximum value. In practice, the maximum temperature is usually limited to 100-125 degrees C by several considerations, which include the reliability of the insulation on the copper winding, and inductor insulation system.

For Additional assistance in inductor designs, contact DRF Engineering Services with your custom inductor design request.

Who We Are:

We are an innovative design and development team, specializing in power electronic circuitry and power conversion products. We primarily provide product design/electrical engineering services, and have worked with cutting edge companies like yours in the past.

Our services include, but are not limited to the following:

- Analog/Digital/Power circuit design

- Linear/Switching regulator design

- Electro-mechanical product design and program management

- Power Management

- Manufacturing support

- Pre-compliance review and test support (certification and test management for IEC and UL)

- Due Diligence and Private Equity Advisory Services

- CAD design services, schematics capture, and board layout