At DRF Engineering Services, we provide well-researched and thorough product development services, beginning with customers’ specific needs and design goals. Our process is based on industry standards for electronics and hardware development and informed by our unique reference design and expertise. No matter the project’s focus, we undertake every project with attentiveness through our unique product development process.

Our Process

Confirming requirements

Before pursuing a definitive solution, the input of our customers is necessary for all projects. It is crucial that we fully understand the customer’s needs and goals. Our process includes in-depth conversations about the customer’s challenges and careful documentation for the project. To ensure goals are understood and met, customers are provided with a complete plan for approval.

The requirements of the customer are documented carefully. These include multidimensional aspects such as development, manufacturing costs and times, ease of use and setup, and standards compliance. These are crucial for determining the right solution.

Identifying specifications

Before beginning a project, we separate the system’s specifications into categories, such as electrical, mechanical, and environmental. This distinguishes specific areas potentially harboring challenges and allows the design stage to progress efficiently.

Plan

Next, our team of engineers thoroughly reviews the customer’s requirements and develops a comprehensive plan of the system’s design, including a full set of milestones. Relying on the system specifications categories created during the previous stage, these milestones are risk-assessed. By creating this plan, we are able to recognize and communicate project risks and costs and provide the customer with specific technical details.

Perfecting the system design

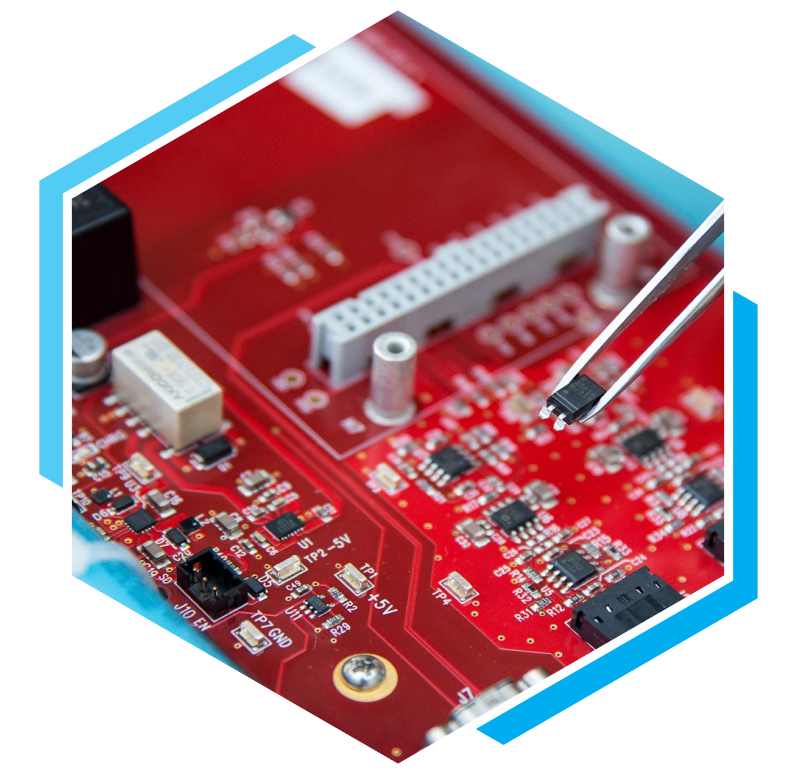

During the design stage, we ensure that all of the technical specifications of the solution are fulfilled so the solution meets its requirements. The design will include a bill of materials, mechanical and electrical drawings, PCB Gerber files, and a thorough test plan. This makes the manufacturing stage possible.

Implementing the design and planning

During this stage of the product development process, the final product is developed in accordance with the design specifications and plan. This often entails manufacturing the final product for the customer. Through our wide network of manufacturing producers, we outsource the production of the product on behalf of the customer. Once the product has been constructed and is shipped to us, it undergoes testing. Testing is recorded to demonstrate the level of success of the products’ individual functions.